Full anatomy zirconia bridge on IPD interface

The client's request: design an all-ceramic bridge with standard titanium interfaces. Our denticians went to work to find the perfect fit.

A dental lab sent us an analogue impression of an obsolete bridge in the patient’s lower jaw with the request to design an all-ceramic bridge with standard titanium interfaces. Our denticians went to work to find the perfect fit.

Case overview in short

- Scanner: Shining 3D

- Software: exocad

- Database and components: IPD

- Production of zirconia bridge: Intellident

- Type of zirconia: Aidite 3D Multilayer (6 layers)

From analogue to digital

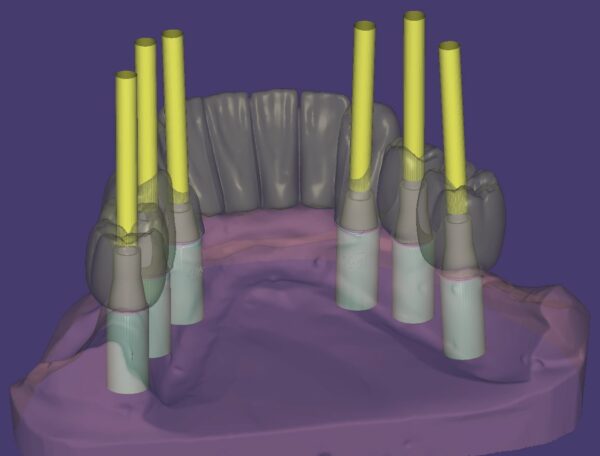

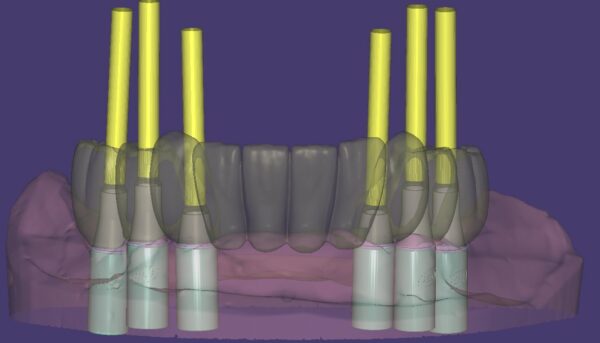

The patient was treated with six implants in the lower jaw. The workflow was as follows:

- The dentist made an analogue impression of the multi-unit abutments already in the patient’s mouth.

- The dental lab created the plaster model and mounted it on the articulator in the correct occlusal relationship.

- The lab also made a duplicate plaster cast of the patient’s old bridge to serve as a reference for the new structure.

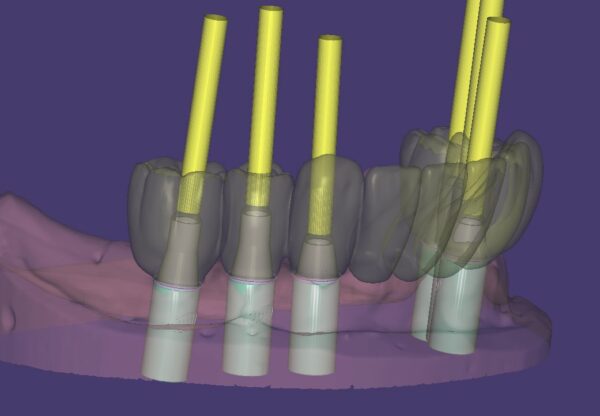

- Intellident then proceeded to the digitisation of the mounted model and the old bridge. We used IPD scan bodies to determine the position of the multi-unit abutments.

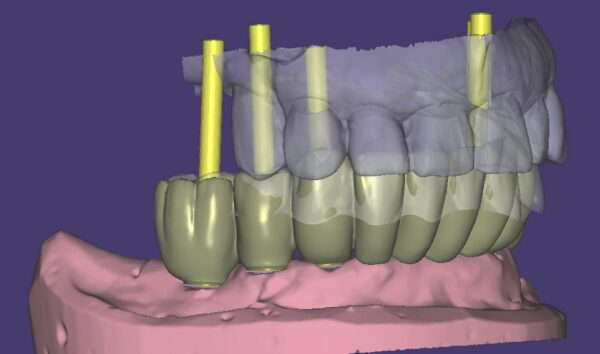

- The new full anatomy bridge was made from Aidite zirconia and provided to the customer.

- Final finishing was done by the dental lab.

Our added value for the customer?

Three factors ensured the perfect fit on the initial analogue model: a strong internal expertise, an extensive product range and the right milling partner.

One of the key issues in this case was the patient’s high vertical dimension of occlusion. Thanks to IPD’s extensive 3D range, we were able to combine low and high interfaces to provide additional support for the ceramic bridge.

When designing the bridge, our denticians also considered the worn areas clearly visible on the old bridge provided by the dental lab.

Last but not least, the expertise of our partner manufacturer also played an important part in achieving an optimum end result. The multilayer blanks in their range – not only in the required height, but also suitable for long-span bridges – enabled the production of an Aidite zirconia bridge.

How can we strengthen your dental workflow?

Intellident’s greatest strength is our capacity to intervene in any step of your dental process. Our experienced designers are building on a product knowledge and database of almost 20 years in a wide variety of cases. This enables us to provide a unique solution for you and your patient.

We would love to hear what case you have in store for us. Contact us and we will get back to you soon.